Is the past actually the future for maintenance?

By Peter Gagg, CEO, MCP Consulting Group Ltd.

The world is a very different place today from the one it was 30 years ago and it is very hard to predict how it will look in another 30 years. The world has become altogether faster and more responsive to changing global markets and customer demands. In the world of maintenance, businesses have adapted their infrastructures to exploit changes in technology and have harnessed a wider skills base than previously required.

With all this change, one would think that the issues faced by maintenance teams today would have also changed – but have they?

1991

In 1991 Lord Reay, the Minister for Industry at the time said, “It has been clearly shown that the use of appropriate maintenance techniques can give companies significant improvements in efficiency and directly enhance profitability.”

This is as true today as it was in 1991!

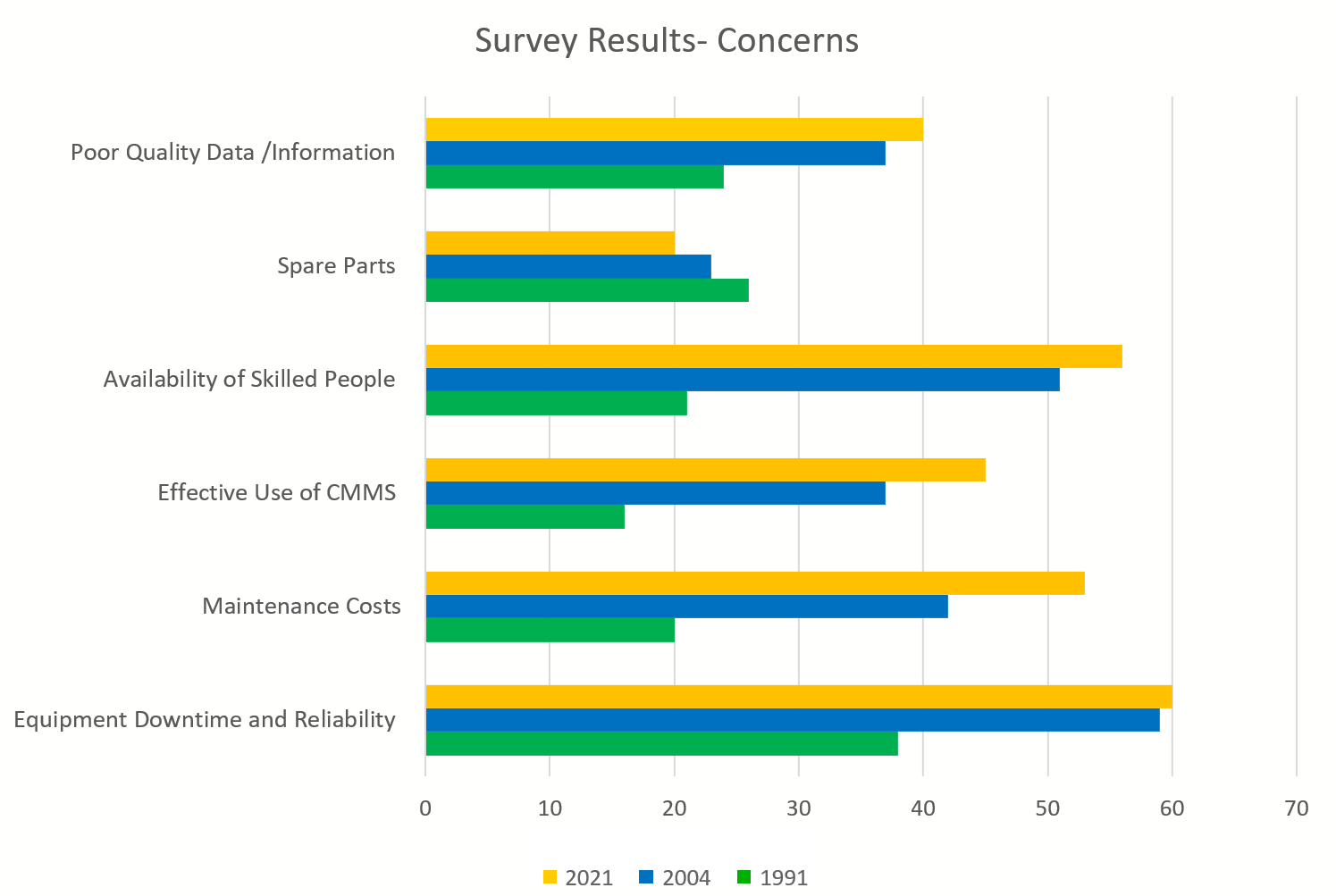

For 30 years, MCP has conducted periodic surveys of maintenance, across all sectors. These surveys show that the common issues and concerns from all those years ago, are actually just as relevant today.

What are the main issues?

Some businesses have evolved and successfully adapted their maintenance over the years to achieve World-Class status. However, many organisations are simply not positioned to succeed in a future world. Some of the reasons for this are because there is:

A lack of maintenance strategy and alignment with the business

An ineffective use of software

Lots of data but little information

A lack of control of contractors and outsourced service arrangements

A shortage of trained technical staff

Work planning and recording systems that are not installed or used correctly

Poor data quality with regard to spare parts coding

A belief that maintenance is responsible for all lost output and equipment stoppages

An inability to identify the full costs of maintenance at job level

How can organisations succeed?

There is no magic wand here! To find the route to success, action needs to start right now to refocus and rebalance for the future. This can be done by:

Using proven tools and techniques to modify maintenance regimes that have never been delivered consistently and will not be delivered in the future

Implementing formal identification, prioritisation, authorisation, planning, control and recording process for all maintenance work

Resolving why spare parts are not available when required, or of the appropriate high-quality

Resolving inadequate technical skills for equipment maintenance regimes

Revising maintenance plans to take care of poor equipment condition

Is technology key?

There is absolutely no doubt that technology should and will form a huge part of any business’s maintenance regime, particularly if it wants to make sustainable changes and become more effective and efficient. Technology can do what us humans can’t or don’t want to do! Many businesses have tried to embrace technology and failed at the first hurdle; it is dismissed as too expensive, too complicated or dehumanising maintenance functions. Reasons for failed attempts while trying to utilise technology include:

CMMS requirements are based on a wish list rather than understanding what is actually required to drive value objectives

Implementation with poor data or inadequate data sets

Systems not fully implemented

Systems that do not support the natural workflows and shop-floor decision making processes

Systems consuming effort due to data entry and providing no value to craftsmen, production, shop-floor, etc.

Little understanding of the benefits to technicians of the technology

Action from data analysis is missing

Technology alone is not the answer!

If technology is embraced and implemented correctly, with the buy-in and collaboration from senior staff through to the shop floor maintenance teams, with a clear, achievable strategy and defined inputs and outputs, the future can most definitely be brighter for your business.

What is the future for maintenance?

So, how will maintenance shape up in the future? To ensure that your maintenance is heading in the right direction there needs to be:

Consideration of through-life management of assets

Understanding asset condition, life expectancy and maintenance requirements

Capital requirements justified on the basis of risk to business and equipment performance

Increase in the use of predictive maintenance tools

Smart Technology, for documents, data, parts and online diagnostics

Effective use of software applications and data analytics

Maximised skills of workforce

Increased focus on safety, reliability and human factors

Asset management (ISO 55000)

Also, never forget the basics! The basics of maintenance include simple processes for planning, reliability, continuous improvement and defined roles. All of these should not be driven but supported by necessary software tools.

How will your business benefit?

Facing your maintenance issues head on can be a daunting task but there is a myriad of proven benefits your organisation can achieve in the not-too-distant future, which include:

Productivity step changes (40–80%) in months rather than years

Typical removal of 35–50% of ineffective preventive maintenance hours

Reduction of 35–50% in unplanned breakdown maintenance

Equivalent reductions in spares usage

Reduced energy and utilities costs

Motivated workforce – continuous improvement

Lean organisations

Design for reliability and maintainability

Predictability and business alignment

Need help?

For over 30 years, MCP has worked with some very well-known brands such as GSK, Diageo, Johnson & Johnson, Jaguar Land Rover and Dubai Airports, to name just a few! We provide our clients with consultancy and training services covering all aspects of their plant and asset maintenance, both throughout the UK and abroad. Our service offering is expansive as are the industries we adapt them to.

MCP has delivered improvement programmes worldwide,

with a typical ROI of 200% within the first year,

delivering the highest possible levels of efficiency and reliability.