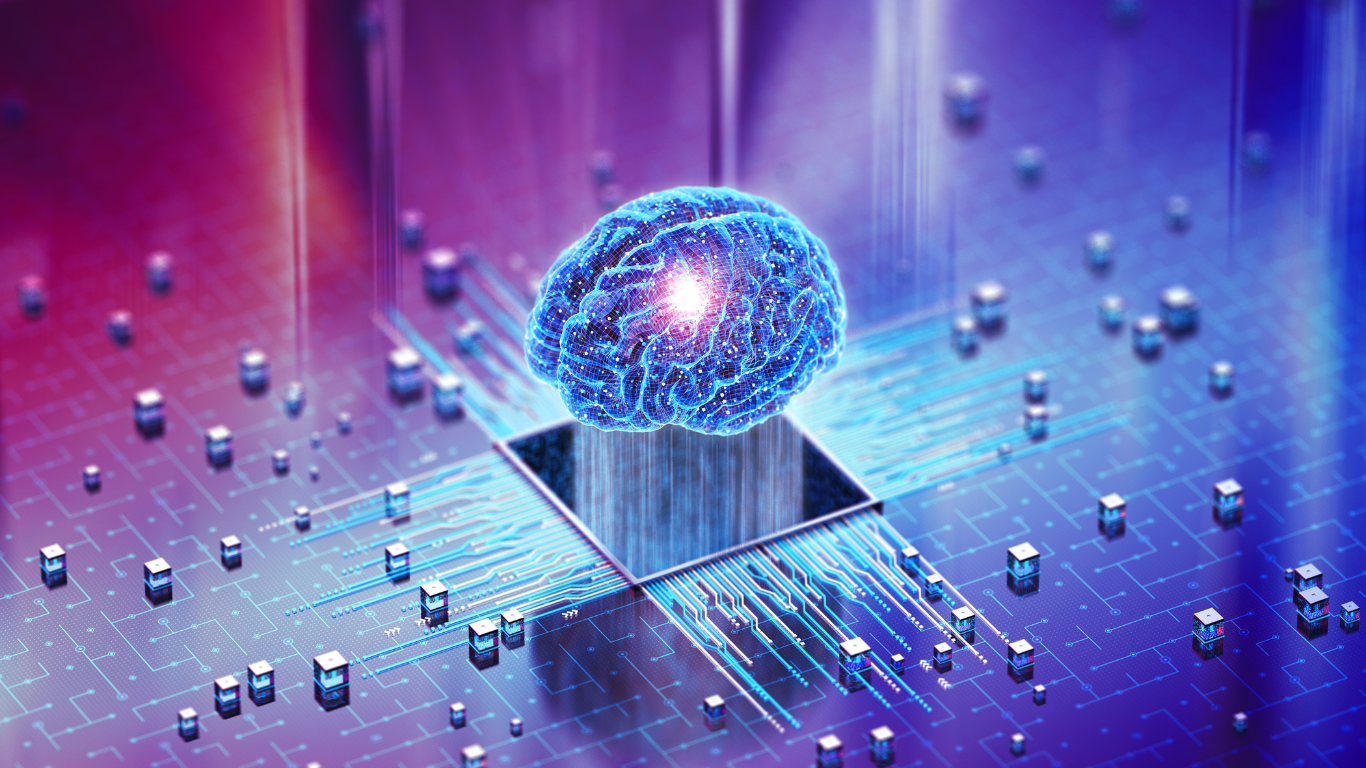

AI and Machine Learning in Maintenance

Artificial Intelligence (AI) and Machine Learning (ML) are transforming maintenance strategies by enabling predictive insights, automating decision-making, and optimising asset performance. At MCP Consulting Group, we help organisations integrate AI-driven maintenance solutions, ensuring reduced downtime, cost savings, and enhanced operational efficiency.

DIGITAL SOLUTIONS CATEGORIES

What is

AI and Machine Learning in Maintenance

AI and Machine Learning use advanced data analytics, pattern recognition, and automation to predict maintenance needs, optimise workflows, and improve asset reliability. These technologies allow businesses to transition from reactive and preventive maintenance to a predictive and prescriptive approach, improving efficiency and reducing operational risks.

At MCP, we support organisations in identifying, implementing, and optimising AI-powered maintenance solutions, ensuring seamless integration with existing asset management systems.

Key Objectives of

AI and Machine Learning in Maintenance

Predictive Maintenance and Failure Prevention

1

Use AI-powered analytics to forecast potential failures and take proactive measures to prevent downtime.

2

Automated Fault Detection and Diagnosis

Leverage machine learning algorithms to detect anomalies and diagnose asset health issues before they escalate.

Optimised Maintenance Scheduling

3

AI-driven insights help schedule maintenance activities based on actual asset conditions, reducing unnecessary servicing.

Cost Reduction and Resource Optimisation

4

Improve efficiency by minimising reactive maintenance costs and reducing manual intervention.

5

Enhanced Asset Lifecycle Management

Extend asset life by predicting wear and tear trends and applying data-driven maintenance planning.

Seamless Integration with CMMS & IoT Systems

6

AI-powered maintenance solutions integrate with CMMS, IoT sensors, and digital twins, providing real-time insights and automated workflows.

MCP Approach to

AI and Machine Learning in Maintenance

AI Readiness Assessment and Strategy Development

MCP helps organisations assess their AI maturity and develop a structured roadmap for AI integration in maintenance.

Predictive Maintenance Implementation

We support businesses in deploying AI-powered predictive maintenance tools, using real-time sensor data and analytics to detect potential failures.

Machine Learning Model Development and Training

Our consultants assist in building and training ML models tailored to predict asset failures, optimise maintenance cycles, and automate fault detection.

AI Integration with Existing Maintenance Systems

We help organisations integrate AI-driven analytics with CMMS, EAM, and IoT platforms, ensuring seamless asset tracking and automated maintenance workflows.

Continuous Monitoring and AI Model Optimisation

MCP can support your long-term success with monitoring AI performance, refining models, and providing ongoing AI-driven maintenance improvements.

Digital Asset Management

Explore More

Speak to One of Our

Experienced Consultants

If you have any questions or would like to learn more about how MCP Consulting Group can support your organisation with AI and Machine Learning in Maintenance, please get in touch with us. Our team of consultants is ready to provide tailored solutions to enhance predictive maintenance, automate diagnostics, and drive AI-powered asset management. Contact us today to discuss your specific requirements.

FAQs

-

AI predicts failures, automates diagnostics, and optimises maintenance schedules, reducing downtime and improving asset performance.

-

Predictive maintenance forecasts failures before they occur, while prescriptive maintenance recommends corrective actions based on AI-driven insights.

-

Yes, AI solutions can seamlessly integrate with CMMS, IoT sensors, and digital twins to enhance real-time maintenance tracking.

-

ML algorithms analyse historical data and real-time performance metrics, helping businesses make data-driven decisions to extend asset life.

-

AI-driven maintenance is used across manufacturing, utilities, energy, healthcare, and transportation to optimise asset performance and reduce costs.