What Does World-Class Look Like?

While rooting through our archives for case study examples of our achievements with customers for Operational Excellence, we came across an article that we wrote for the Asset Management section of the ME Plant & Maintenance Magazine. Although this article was written early in 2015, the words still resonated with us and are still pertinent today. So, we thought we would re-write this article and share with you, just in case you didn’t have a back-copy of the magazine!

What does World Class Asset Management look like?

The term ‘World Class’ is used frequently to describe a 'high performing' site, but what do we actually mean by this?

World Class is often:

Described as being innovative, lean, efficient, cost effective and flexible.

Seen as a collection of concepts, which set standards for production and manufacturing for other organisations to follow. Japan is credited with pioneering the concept of world-class manufacturing, where it was introduced in the automobile, electronic and steel industry after the war.

A process driven approach where various techniques and philosophies are used in one combination or other.

To achieve world class status amongst a company's peers demands the delivery of world class asset management together with high plant reliability. Both crucial components to improving operational performance, but that is not all.

Too often we think of improved processes and technical techniques in terms of systems and equipment reliability. The overriding message for us is that improvements can only be fully achieved with the engagement in the process, of all people together, with a far-reaching cultural change.

What do MCP recognise as World Class Asset Management from global participants in the AMIS benchmarking system?

A World Class Team is proactive, not reactive.

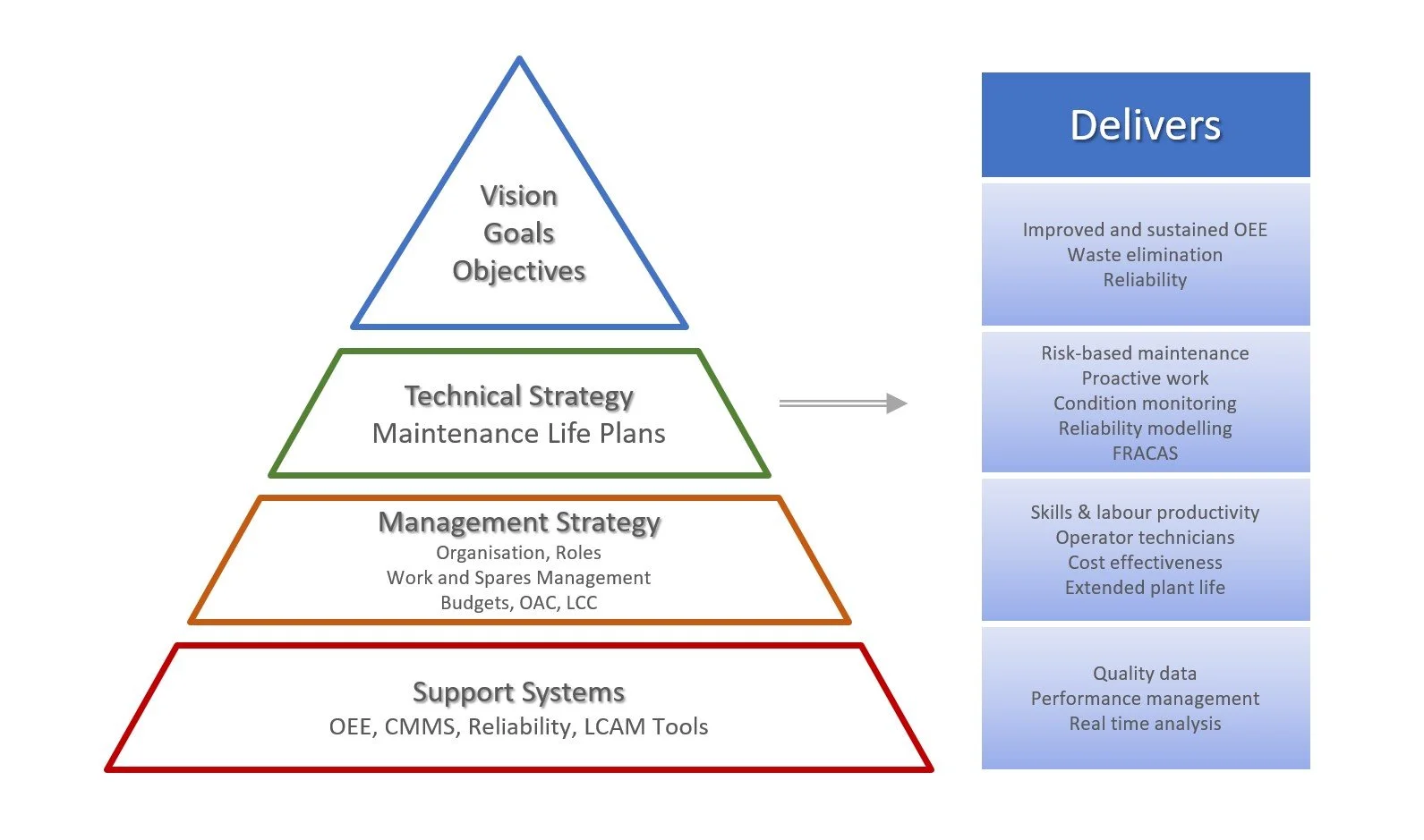

A clear and documented asset care strategy, built on good foundations, such as reliability analyses and effective planning, is needed to drive a step change improvement in plant performance and reliability.

A World Class asset management strategy should incorporate the following:

Organisation structure and roles

Establish maintenance plans using reliability techniques

Workload planning and control

Cost-effectiveness analyses

Productivity and maintenance effectiveness

Materials management

Continuous improvement and failure analysis

Early equipment management

Training and safety

Computerised maintenance management system (CMMS)

Motivation, culture and people management — however many improvement processes are implemented, you will still fall short of world class, if you do not look at motivation, culture and people management.

A World Class Team analyses performance and sets targets

Operator asset care and continuous improvement are two specific work streams that build on the foundation to ensure processes are owned by local teams and the desired culture change takes place. Key Performance Indicators (KPls) are selected for each process to enable the local teams to analyse performance and deliver improvements. The KPls are developed and used as leading or lagging indicators depending on process delivery. Correct systems configuration is vital to produce these KPls which can then be trended and visualised on team boards for use by local teams, with ongoing sponsorship from senior management and team leaders.

Each role should be trained to be aware of their accountability and should have a minimum of one KPI to be able to claim they are involved with asset management. Targets should also be agreed with each individual in their regular performance assessments. Detailed training should then be provided with a method to demonstrate competences against each defined process.

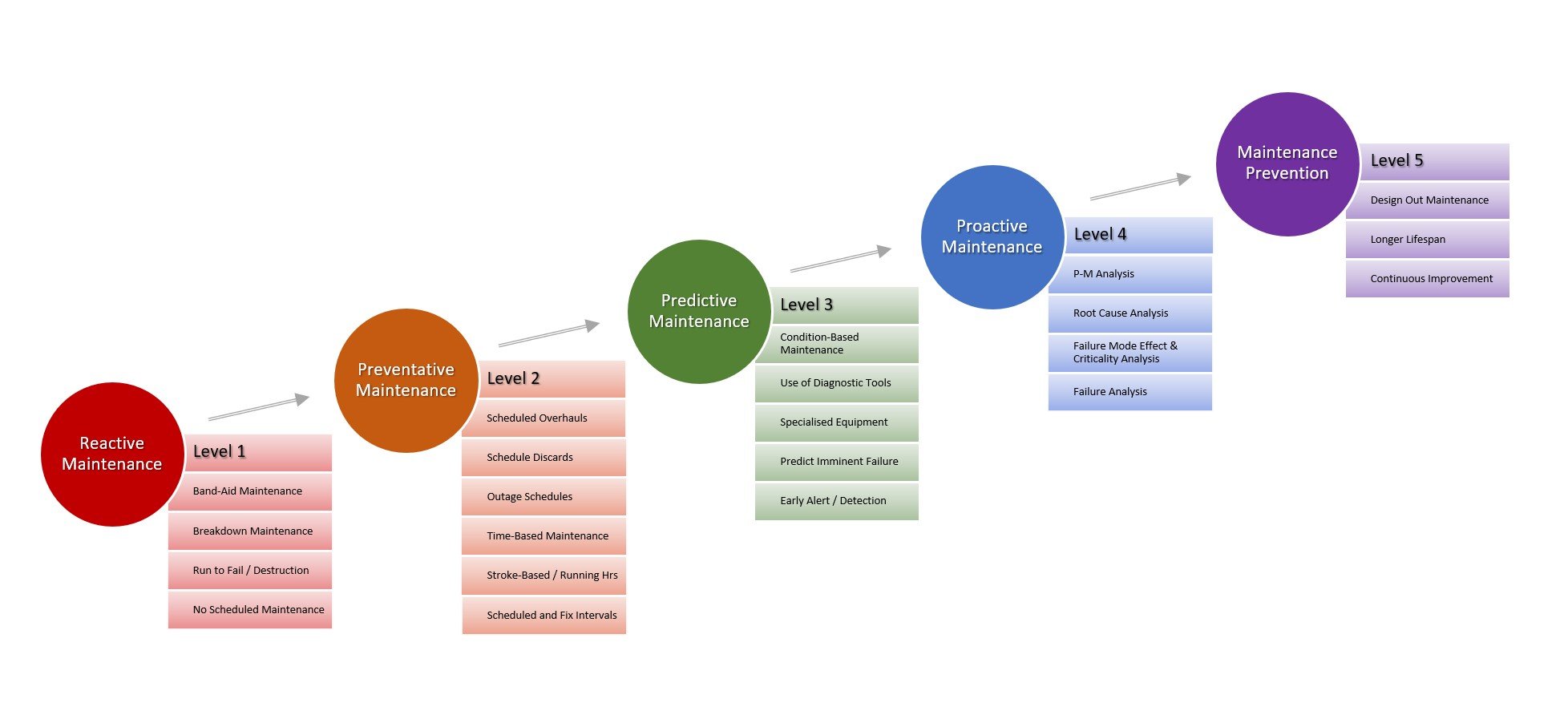

Once the processes are matured, the overall business goals are delivered with exceptional targets agreed and delivered, for example; profit, OEE, reliability and downtime. A typical journey is depicted in Figure 1.

Figure 1. A Typical Journey

A large number of global companies have now participated in the AMIS process as part of their journey to World Class manufacturing across all their multi-sites around the world. The progress for one typical global multi-site client, in the food and drinks sector, is shown in Figure 2.

Figure 2. Example AMIS Progress

The Asset Care Excellence (ACE) journey also sets targets for exceptional plant targets by segment type within any sector, for example; process, packaging, facilities, R&D and services.

An example of KPls and targets used to demonstrate delivery of performance for a packaging site includes:

PM selection — balanced tasks between craft PMs, operator checks, predictive tasks etc — e.g., operator checks >20%

PM completion — target 100%

Work arising from PMs — notifications raised with > 60% from operators

Backlog < I month

Adherence to plan >95%

Planning effectiveness to measure planned work and utilisation >80%

Cl activities >20% (replace reactive work with agreed CI, e.g. REM, RCA, etc)

Annual upkeep cost = f/capital asset replacements value (CAW) 3%

sites seen as high as 10% of CARV spent on maintenance annually with downtime at > 12%

o£/M2 targets used in facilities sector

Downtime <I% engineering downtime (CMMS history should have cause identified and matching manufacturing OEE analyses)

Data quality >95% (ensures cost, spares, root cause properly booked and failure field trigger to provide MTBF and MTTR)

OEE >75%

Availability >90% (all stoppages)

Reliability (MTBF) and maintainability (MTTR) compared by generic equipment type and shared with OEMs

A World Class Team inputs, collects and uses data from the CMMS

Data should be available from the manufacturing OEE system as well as the maintenance CMMS. The planner's role should also include the data analyst function to provide quality information to each team/role. The local team board should then include the relevant performance trends for team ownership and regular team reviews.

A World Class Team uses Root Cause Analysis to eliminate reactive work

Figure 3 indicates the AMIS Journey with planning effectiveness showing how the craft weekly work profile has moved over 3 years from 10% proactive to 85% proactive, with the elimination of failures and reactive work (through root cause analyses and operator asset care). Many packaging sites misuse 30% - 0% of craft time on low tech.

Figure 3. Mean Time Between Failure Overall

A World Class Team considers the total life span of their assets

The through-life approach is also covered with two separate work streams covering:

Early Equipment Management (EEM) — defined vertical ramp-up to agreed World Class OEE within target date, etc.

EEM assessments show clients average at 40% against World Class at 75% (i.e. projects take sites back into reactive regime)

Projects usually delivered to time and cost but not to agreed plant performance e.g., vertical ramp-up to World Class OEE

Asset replacement decisions using condition grading, system KPls e.g., MTBF, MTTR, E/CARV to decide whether to repair, refurbish or replace (i.e., annual 3R decisions to feed into 5-year budgets)

Annual condition grading surveys would measure against As-Good-As-New (AGAN) standards

A World Class team establishes a holistic approach to improvement

All the above points show that a more holistic approach is required to deliver exceptional plant performance. Too many companies select one option e.g., RCM, planning or TPM and do not cover all processes. Similarly, high level sponsorship is often missing as the business driver has only been to produce a high-level strategy document resulting in few processes owned at local level.

Some companies chose Lean without addressing the reliability issues and often the craft team have to respond to leadership demands and resort to a reactive regime with increasing waste. Operator asset care is a fundamental pivot for exceptional plant performance linked with Standard Operating Procedures (SOPs) and competences starting with the establishment of equipment competent operator skills.

A World Class team is engaged

The AMIS process looks at all the required aspects and the use of process maps provide a tool for local teams to be engaged. The benchmarking process measures the rate of change in terms of engagement and provides appropriate training to empower each role, with accountabilities defined. Targets for improvement can be established and triggers provided to get team leaders and sponsors involved, see Figure 4.

Figure 4. Targets for Improvement

Competences are a key part of the overall programme and progress on training should be regularly reported alongside PMs Completion, as per HSE guidelines in the UK. Awareness training of the intended ACE strategy is often missed and therefore the intended strategy is never fully applied by the relevant people.

Process conformance should then be regularly analysed and capabilities ensured. Visuality is a key provision with each process owner defined and targets agreed per individual. Regular team reviews using the visual storyboards will provide engagement and ensure conformance as well as further enhancement for example; Review Existing Maintenance (REM), SOPs amended and training. One good example would be the craft technician analysing reactive work each month that did not require tools or spares and discuss with operating colleagues whether the tasks should be included within the operator SOPs and skills profiles.

A World Class team shares success

Finally, benefits are regularly tracked to recognise the contributions and share success. Senior management need to regularly review performance and set challenging targets to sustain the performance. The loss analyses process should be visible and used to trigger the next improvements. Perhaps it would be interesting to measure your plant's performance against these exceptional targets in your own sector?

Introducing AMIS

For over 30 years, the Asset Management Information System (AMIS) benchmarking process has been used globally with a large number of participating sites, from each industrial sector, ranging from nuclear, oil and gas, through manufacturing to utilities and facilities. As well as benchmarking, it is also an improvement journey to deliver World Class performance. AMIS was initially sponsored by the UK Government's Department of Trade & Industry to reduce waste and improve the performance from the huge investment in industrial maintenance - it is now used globally - in all sectors.